Recently, Narada achieved a dual breakthrough in high energy density and high safety solid-state battery materials and processes, promoting advancements in solid-state battery technology.

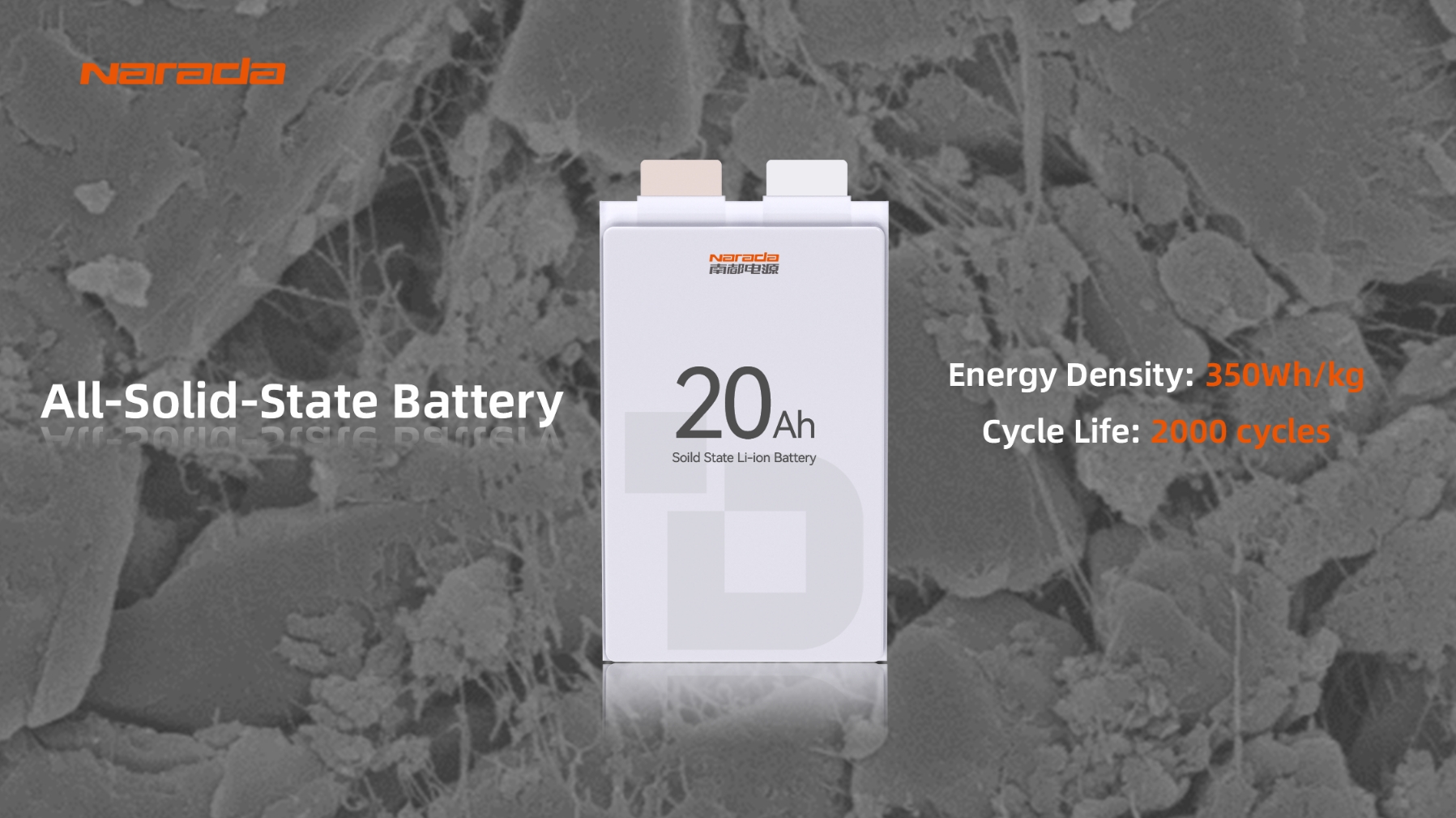

The successfully developed 20Ah all-solid-state battery is based on an ultra-high nickel ternary positive electrode and a confined growth silicon-carbon negative electrode system, with an energy density reaching 350Wh/kg and a cycle life of 2000 times. It has passed safety performance tests such as extrusion and short-circuiting, meeting national standards. The battery does not catch fire or explode.

Resolving Material Technical Challenges for Further Performance Breakthroughs

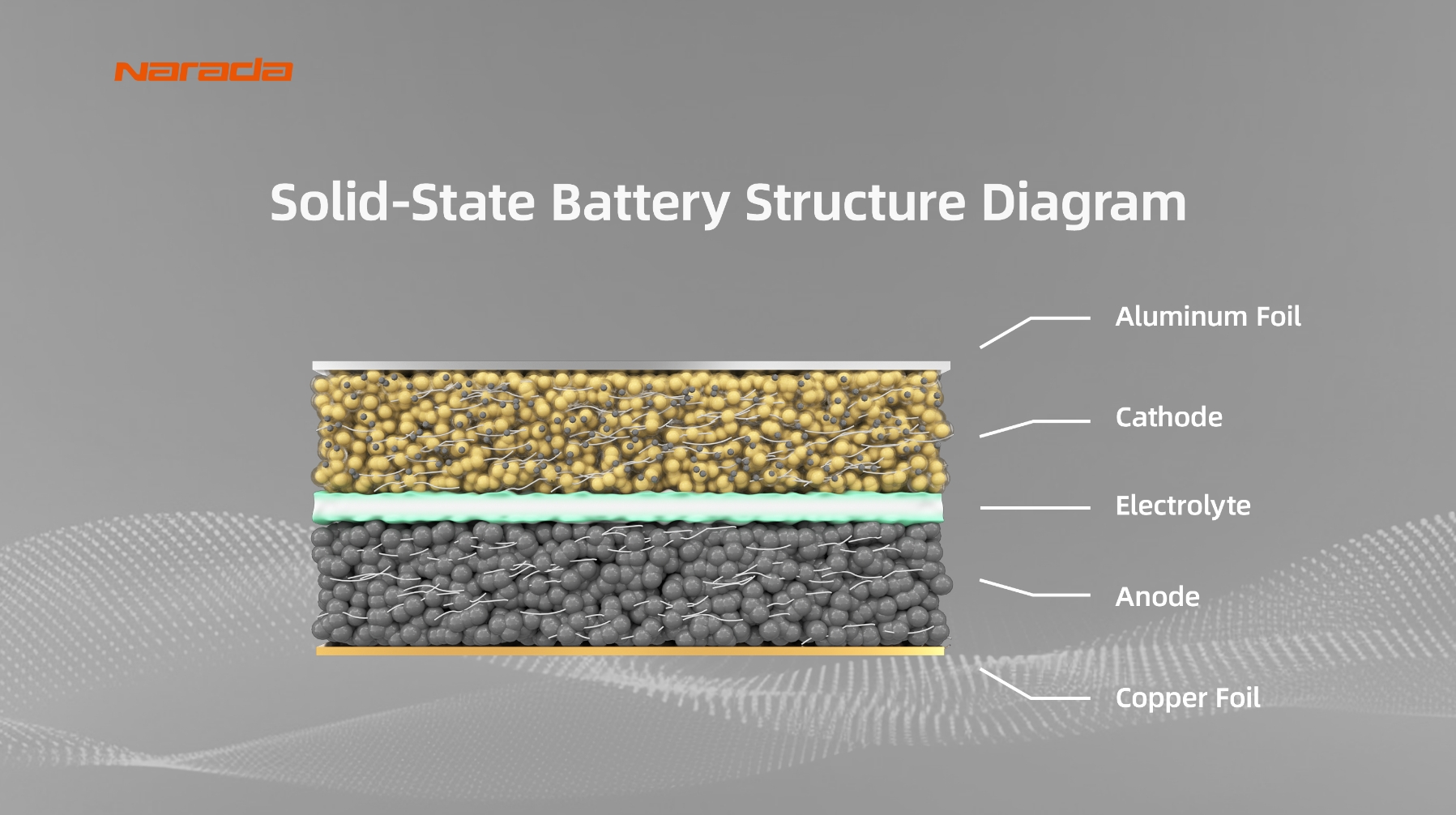

The key to solid-state battery technology lies in the solid electrolyte, enabling both high energy density and safety. Narada's solid-state battery uses independently developed inorganic oxide solid electrolytes, eliminating the safety risks associated with liquid organic electrolytes.

Oxide solid electrolytes possess relatively high ionic conductivity and are well-balanced in production processes, manufacturing costs, and electrochemical performance. However, their brittleness and high interface resistance have limited the large-scale industrialization of all-solid-state batteries.

Narada has introduced toughening materials into the solid electrolyte, enhancing its overall mechanical strength and significantly reducing the likelihood of internal short circuits.

Additionally, the battery features a sandwich structure design for the electrolyte and in-situ film formation technology on the electrode surface, greatly improving the interface contact performance between the solid electrolyte and electrodes. This reduces internal resistance and effectively resolves the "solid-solid interface" issue, enhancing the cycle life and rate performance of all-solid-state batteries, thereby accelerating their large-scale application.

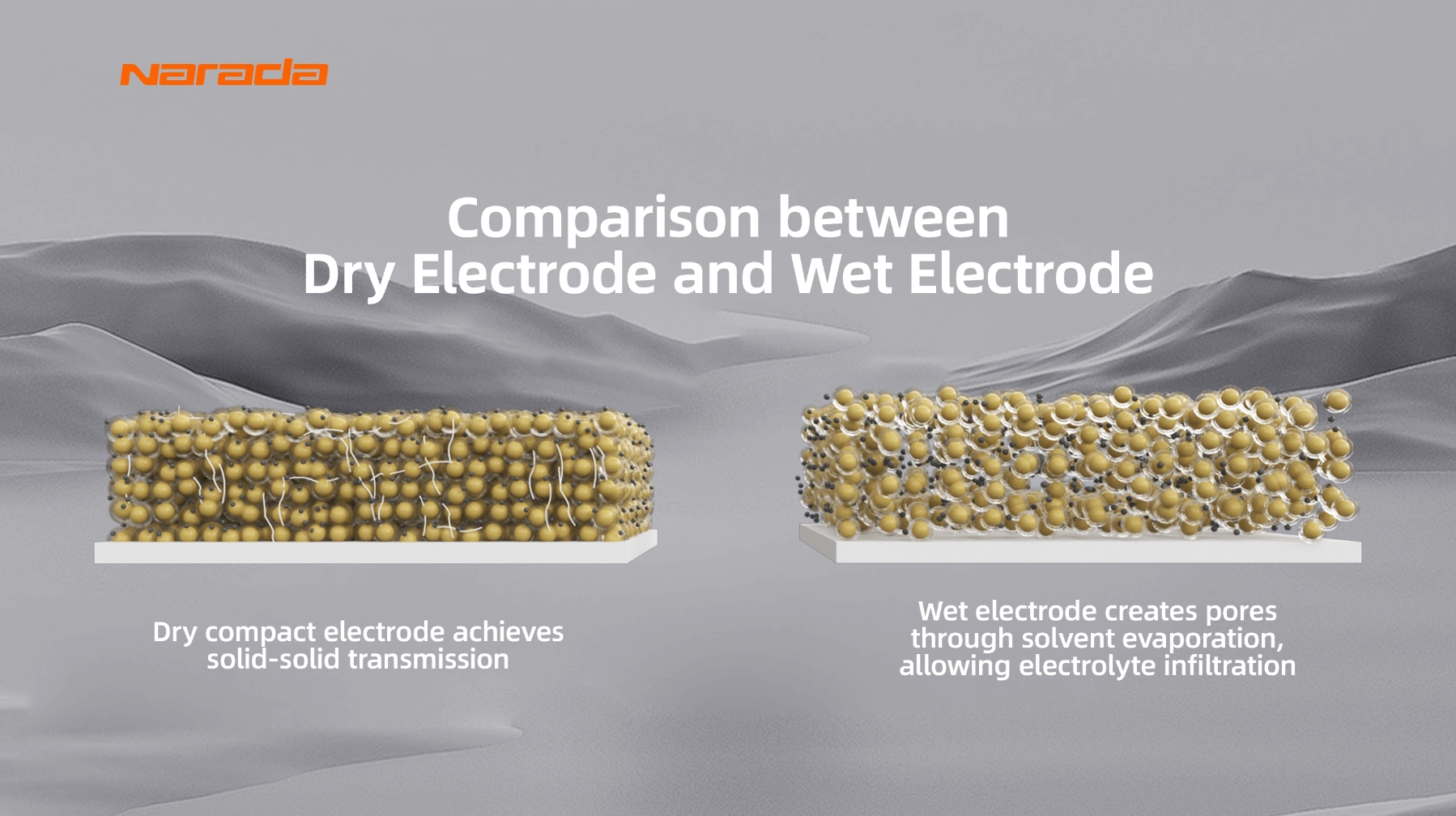

Dense Electrode Dry Process to Drive Industrialization

To further address the industrialization challenges of the "solid-solid interface," Narada developed a dense electrode dry process that significantly reduces electrode porosity, achieving a density of over 80%. This ensures close contact between the active materials and the electrolyte, resulting in conductivity that is significantly higher than that of wet processes, while also improving battery energy density.

Moreover, the dry process eliminates the coating and drying steps, offering a notable cost reduction advantage—lowering electrode manufacturing costs by 10%-15% compared to traditional wet processes. Narada is one of the first companies in the industry to develop this dry process, greatly advancing the industrialization of its solid-state batteries.

Wide Temperature Range Capability to Meet High and Low-Temperature Applications

On a safety foundation, Narada seeks breakthroughs in battery performance. The Narada solid-state battery can operate in a wide temperature range of -20℃ to 85℃, covering most extreme conditions. After 500 full charge-discharge cycles, it retains 93.4% of its capacity, and after 2000 cycles, the capacity retention is greater than 80%.

The solid-state battery displayed at the EESA exhibition showcases these performance enhancements, which significantly broaden its application scenarios, including drones, robots, low-altitude aircraft, and smartphones. Furthermore, at the same energy density, the cost of Narada's solid-state battery is only 10%-15% higher than that of conventional lithium batteries.

As a critical competitive edge in next-generation battery technology, Narada is fully engaged in and deeply cultivating the solid-state lithium battery field, reaffirming its strength in technological innovation and product diversification.

Going forward, Narada will continue to accelerate the industrialization process of solid-state batteries through ongoing research and development in processes and equipment manufacturing.