For many years, Narada has embarked on a journey of innovation, leveraging new technologies, new industries, and fresh talents to drive the high-quality development of the new energy industry, continuously practicing the concept of new productive forces.

Building integrated R&D capabilities throughout the entire lifecycle

Narada leads the high-quality development of enterprises and industries with technological innovation. Over the past 30 years, Narada has persisted in technological innovation and demonstrated its leading strength as a supplier of overall solutions for energy storage, especially in the innovation fields that can form industrial applications.

Narada has established five research institutes, including battery materials, cells and modules, energy storage systems, management systems and resource regeneration, which has formed an integrated R&D capability for the whole life cycle of energy storage.

How can we start with battery materials to extend the cycle life of energy storage batteries, thereby reducing the Levelized Cost of Storage (LCOS)?

Narada has a range of core technologies. One solution involves the use of graphite layer spacing control and lithium pumping technology to address issues with cycle stability and the safety of lithium replenishment.

"On the one hand, the graphite layer spacing adjustment and control technology adopts small particle size single particle material. On the other hand, the use of lithium pumping technology, controlled precisely by an external lithium pump, maintains the stability of the electrode structure and the conductive network, significantly improving the safety of lithium replenishment," said Jiayuan Xiang, Vice President and Chief Engineer of Narada.

Currently, as the capacity of energy storage cells within the industry increases, the overall cost of energy storage systems is reduced and project profits are increased. However, this is accompanied by the pain point of increased difficulty in thermal management.

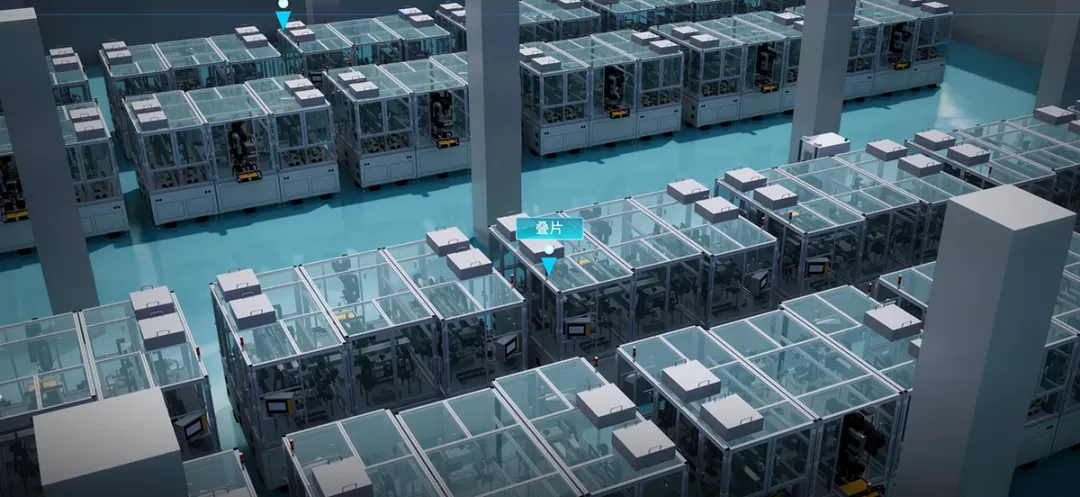

Unlike other manufacturers, Narada chose the lithium battery stacking process for safety and cycle life, rather than the mainstream winding process from 20 years ago.

The stacking process achieves higher energy density compared to the winding process. Moreover, during expansion and contraction, the electrode plates remain flat, ensuring even stress distribution without the problem of stress concentration at curved corners, making it safer to use. Additionally, with the introduction of the new generation of high-speed stacking equipment, the production efficiency of the stacking process is approaching that of the traditional winding process.

The balance of cell temperature determines the life and efficiency of the energy storage system. Narada's new energy storage system, released in 2023, adopts a liquid cooling temperature control method. Through multi-stage variable diameter pipeline design, dual cooling circuits design, and real-time cooling fluid leakage monitoring, it achieves a temperature difference of less than 3°C within the PACK, effectively extending the life of the cells. Furthermore, the liquid cooling system can intelligently adjust the cooling efficiency based on actual operating conditions, significantly reducing auxiliary power consumption.

How are customers' individualized customization demands for energy storage systems realized through design?

Narada engages in differentiated design based on various functionalities such as peak shaving, frequency regulation, and black start capabilities. The energy storage stations designed for peak shaving and frequency regulation differ in terms of cell selection and thermal management design. Those equipped with black start capabilities differ from conventional energy storage station designs in their topology and control mechanisms.

The integrated design of energy storage system strategies and controls ensures that safety considerations are fully integrated from the outset of the system design. This includes safety-oriented design and optimization at every level, from the cells and modules to subsystems and the entire system, thereby reducing safety risks.

Moreover, Narada also fully incorporates real-time monitoring and intelligent warning functions in the system design. This allows for the immediate detection and addressing of potential safety issues, elevating safety to a higher level under current technological conditions.

In the field of materials and recycling, Narada has developed comprehensive #Lithium extraction technology, continuously optimizing processes to minimize the loss of lithium in wastewater and emissions, achieving a lithium recovery rate of over 92%.

"The company's iron phosphate resource recovery technology and graphite regeneration technology have made further breakthroughs in 2023, entering the pilot and batch testing stages, respectively," a staff member from the Narada Advanced Materials Research Institute explained.

At present, Narada has been recognized by the National Technological Innovation Demonstration Enterprise and the National Engineering Research Center. It possesses innovation platforms such as a national recognized testing laboratory, a CTF recognized laboratory, a post-doctoral workstation, and an academician workstation, gathering advantageous industry resources for collaborative innovation.

In 2023, Narada successively launched several new products, including 300Ah+ energy storage battery, 20ft 5MWh+ liquid cooling energy storage systems, and the Edge series for industrial and commercial energy storage, characterized by their safety, reliability, and economic efficiency. Narada will also introduce a variety of new energy storage cells and systems this year.

To build new advantages for future development, Narada is actively exploring new fields. The recently established Zhejiang Narada Hydrogen Energy Technology Co., Ltd. will focus on the research of hydrogen production technologies using renewable energy. It will also leverage the main business of Narada's energy storage, with a focus on developing hydrogen energy storage and its downstream application projects. Currently, Narada has developed a reserve of technologies including water electrolysis and flexible hydrogen production coupled with lithium energy storage.

In the future, Narada will continue to accelerate the innovation of energy storage technologies, industrial innovation, and systemic and institutional innovation. We will deeply grasp key points of quality excellence, continuously develop new productive forces, and propel the significant development of the new energy industry.